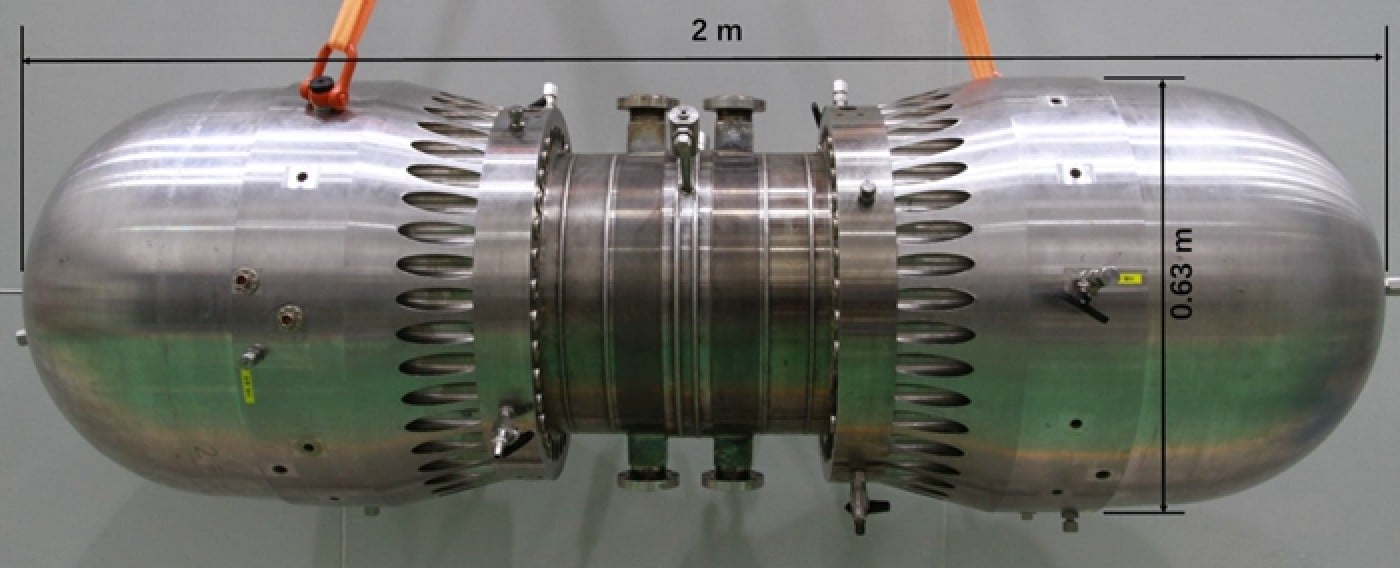

The Chinese generator was created by the Technical Institute of Physics and Chemistry (TIPC) at the Chinese Academy of Sciences (CAS) and is about 2 meters (6½ feet) long and has a dumbbell-like shape.

It works with impressive efficiency, according to Professor Hu Jianying of TIPC.

“Current thermoelectric conversion efficiency is about 28 percent; with a hotter 600-degree thermal fluid, the efficiency can reach 34 percent.

This efficiency can rival steam turbines.

Professor Luo Erkang of TIPC highlighted the generator’s reliability, simple design, lack of moving parts and compatibility with various heat sources.

“It works quietly and efficiently, and can use different types of heat, including solar energy, waste heat, and biomass,” an academy statement quoted Lu as saying.

The innovative system includes a Stirling thermoacoustic motor and a linear actuator encased in a solid shell. The motor converts heat into sound waves that resonate to form a stable sound field. These waves then actuate the piston, which in turn generates electricity.

“High-pressure helium at 15 MPa acts as the working medium, and the absence of mechanical parts that need to be lubricated means the generator can have a lifespan of more than a decade,” Hu said.

While Stirling engine technology – first developed by Scottish engineer Robert Stirling in 1816 – faces manufacturing challenges due to material requirements for containing the high-pressure gas, its low noise and high reliability remain attractive for specialized contexts.

Sweden’s use of it in submarines and China’s developments in using Stirling engines for marine applications underscore the value of this technology. Modern submarines with air-independent propulsion (AIP), including the Chinese Navy’s Type 039A/B submarines, use Stirling engines as a power source.

The thermoacoustic generator developed by CAS not only opens new horizons for conventional Stirling engine designs, but also integrates an engine that directly converts sound into electrical energy.

The design of the motor avoided harmful vibrations and maintained a tight seal inside the mechanism, Hu noted.

“The linear actuator, consisting of a sonic-driven piston, permanent magnets and coils, contributes to the high conversion efficiency. Its symmetrical design also eliminates some of the harmful vibrations.

“The linear actuator maintains a very small space, about the thickness of a human hair, between the piston and the cylinder. This prevents parts from touching while maintaining a sealed internal environment.

Although there is no academic paper associated with the CAS announcement, this achievement highlights the potential of Stirling thermoacoustic generators to revolutionize power generation in diverse fields.

“It is a promising new generation technology for solar thermal energy, biomass power generation and distributed energy systems,” Hu said.

“Freelance web ninja. Wannabe communicator. Amateur tv aficionado. Twitter practitioner. Extreme music evangelist. Internet fanatic.”